Wire Shelves That Enhances the Look And Feel of Your Home

What crosses your mind when you hear the words ‘wire shelving’? Garage Storage? Yes, but it isn’t pretty. I’m here to change that answer. Making you think of wire shelving as stylish, useful, modern, chic, and purposeful. Are you ready for some wire shelving decorating ideas?

Wire shelving in the kitchen

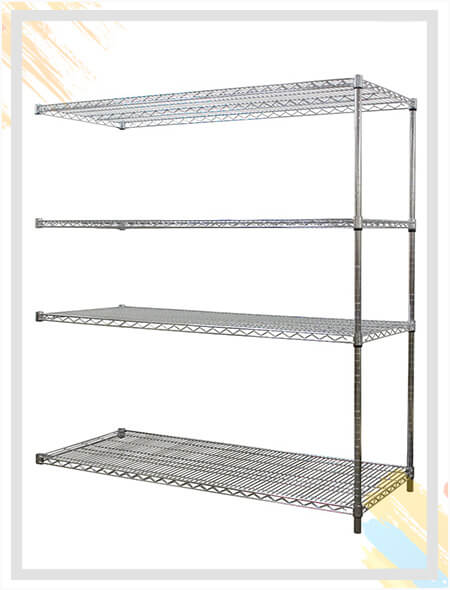

When silver, whites, greens, and soft pinks in the metals all go together beautifully, you almost forget that this is just a mere kitchen shelving unit. To think how the metal in the shelving complements the microwave and the pans and pots are kinds of genius. While this simple unit looks quite chic, it’s still very purposeful and useful in a kitchen.

Although the mixture of wood and metal may have looked really boring and simple, the opposite is true in kitchen wire shelves. This brilliant combination is a perfect canvas, perfect for showcasing beautiful items and special dishes. The versatility of being able to switch the height of wire kitchen shelves also comes in handy, brilliantly highlighting the metal skeleton of the whole unit.

Wire shelving for living rooms

The square shelving has been around for a while and is quite hot. These squares provide just enough of a visual break between the units, offering a contemporary look. The rectangular break in between the bottom and top shelf is very fresh. The visual interest is added not by the typical alphabetical order but by color.

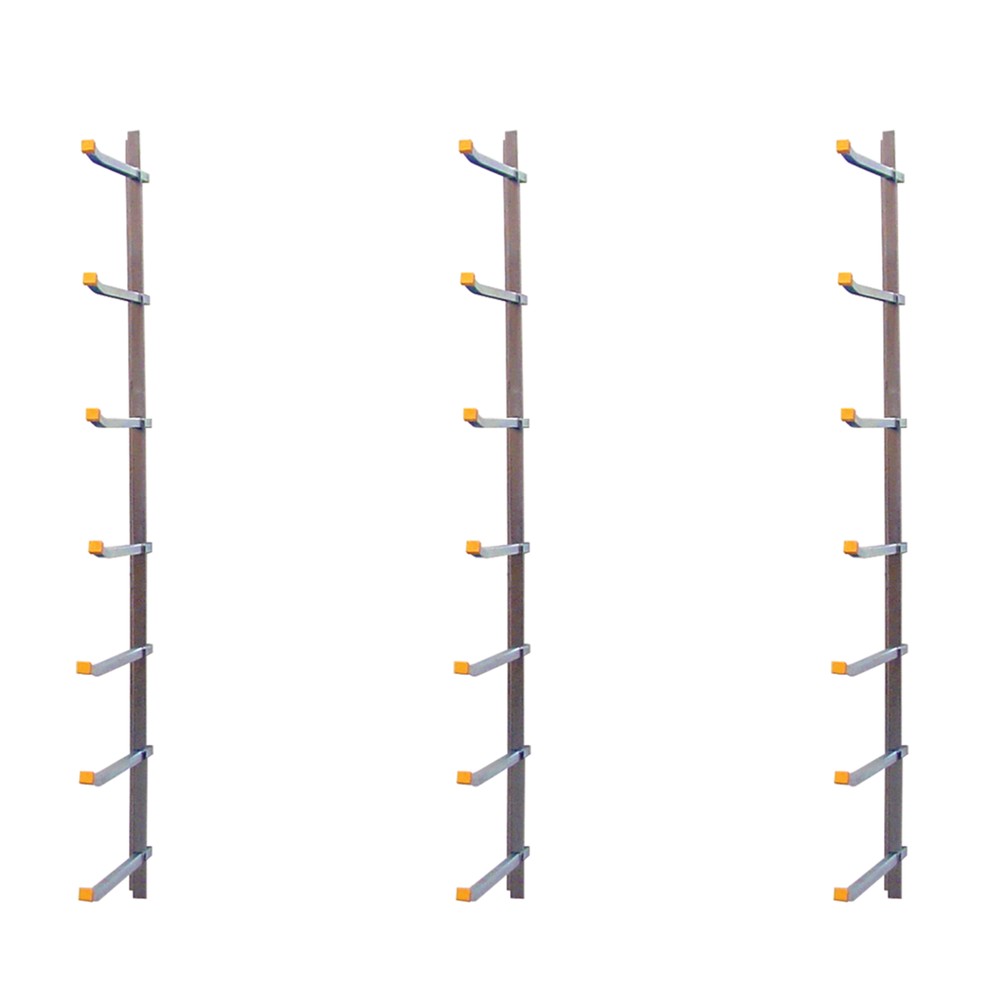

The wire and wood shelves are quite underrated. A mix of wood and wire that really works well is where the shelves aren’t necessarily useful since they’re very close, vertically! A much-needed visual break on such a big unit is added by the design element. Being new and fresh, it adds a bit of attraction to the overall appearance of the String shelving unit.

Wire shelving for bedrooms, workspaces, and bathrooms

This living home wiring shelving is so fantastic that it’s used in a bedroom, still looking very chic, while also creating some amazing storage. This unit or wire bookshelves serve to hold books, accessories, a TV, and even a full makeup area. The good thing about the metal shelving is the fact that it’s neutral, and as you can see, it can be used in a plethora of places.

Another good way is to build a functional mini office, the one that blends into the wall. The use of a ghost chair as an accompaniment complements the lightness, and the wire shelving makes the whole thing look as if it’s floating. This is a brilliant utilization of a small space that becomes not only useful but beautiful as well.