The Best Warehouse Storage Solutions

When you work in a warehouse for a long period of time, you start to think that you’ve seen everything. You know exactly where everything goes, what type of warehouse shelves you need to use, and you feel like everything is under your control.

But there’s one thing that we all have learned: there’s always a new type of storage to try out in warehouses of any size, irrespective of what you have to store. We enlighten you with our favorite five warehouse storage solutions that you didn’t know you needed.

Pallet Rack Wire Decking

In terms of wire storage solutions, warehouse pallet racks top the list. A large number of people love their pallet racks, subsequently assuming that everything is established so long as the shelves remain intact, but that’s not the case. Finding the appropriate pallet rack decking may actually go a long way towards keeping your shelves safer overall, more visible, and better organized. Wire decking may help you in separating the products better, support more weight than usual decks, and assist you in finding items more quickly with greater visibility.

Wall-Mounted Shelves

In the warehouse, wall mounted wire storage shelving may actually serve a lot of uses. Try hanging them around your facility at strategic locations to help better organize receiving and shipping areas, help tidy up common areas like break rooms and cafeterias, and provide easier access to needed supplies, for example, toolboxes, gloves, and hard hats.

Shelf Tracks

Many warehouses have a carton flow solution, which aids in moving products from one area to another. But what about shelves that assist you in moving product across the individual racks? Shelf tracks assist in moving products with the durability and speed of a gravity rack, except they’re installable on shelf racks, reducing the hassles associated with heavy boxes and large shipments and facilitating in moving products more quickly.

Record Storage

A large number of businesses need to have physical, hard copies of their records for numerous reasons, typically to comply with federal regulations. Even if they’re just sheets of paper, these documents may pile up after a while. If your warehouse needs to keep tax paperwork, bills of the manifest, or shipping records for an extended duration, high-density record storage is a low-profile, great way to keep these records exactly where you need them.

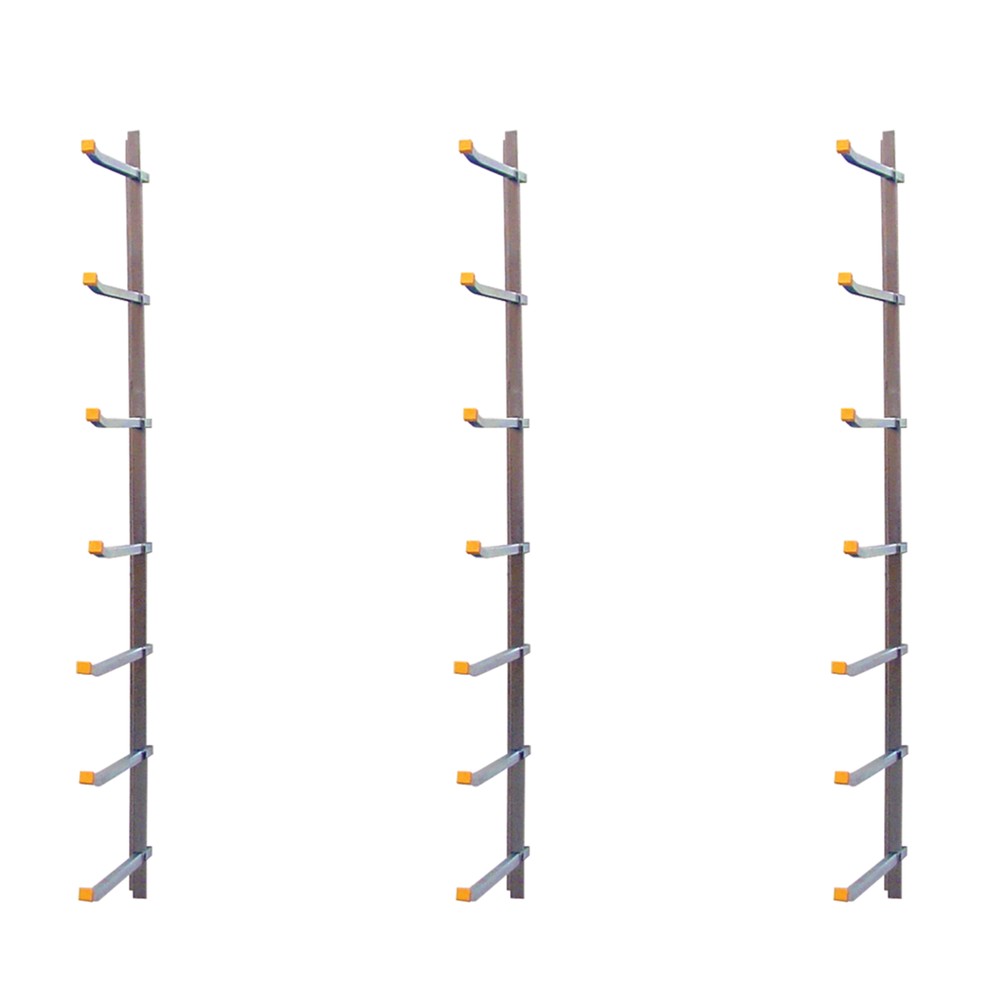

Bulk Storage Racks

In cases where your goods are bulkier that need to be accessed without the existence of powered lift equipment such as forklifts, bulk storage racks are a fireproof, strong, and durable way to help store your heaviest goods in their own dedicated spaces. For this purpose, storage shelves with baskets and storage bin rack may also be used.